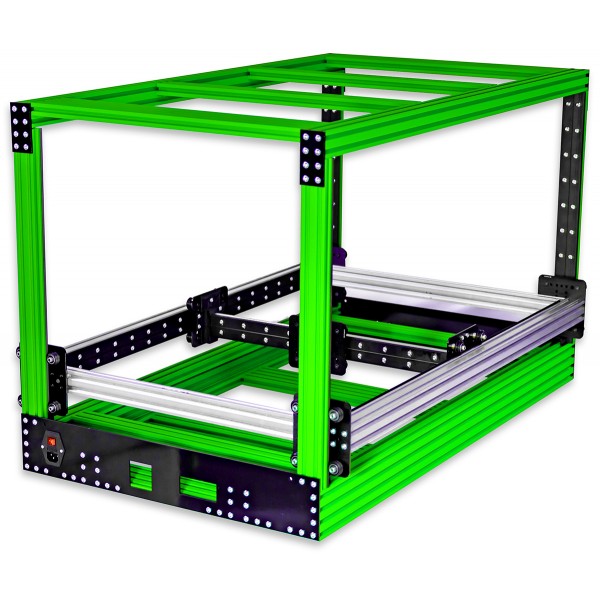

LF1- Long Format Frame Kit

Reference:

Are you looking to upgrade your 3D Printer? Are you a tinker, builder, or experimenting with 3D printing?

Allow us to introduce the revolutionary Stabilus Long Format (LF1) 3D Printer Kit that will elevate your hobby or trade to new heights!

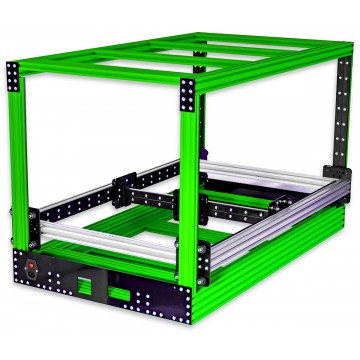

Choose your frame with an aluminum finish, or pick one of 5 colors during checkout. Email us for additional colors!

Take your printer to the next level with LF1!

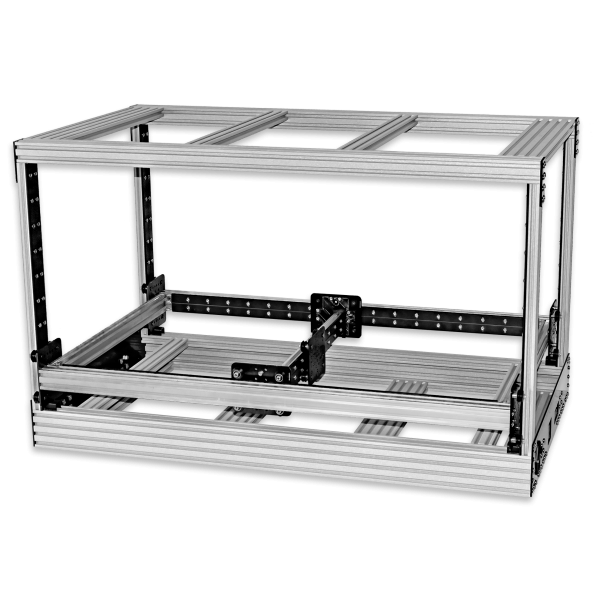

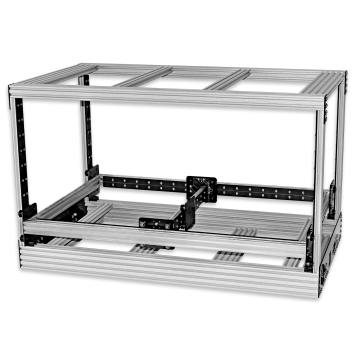

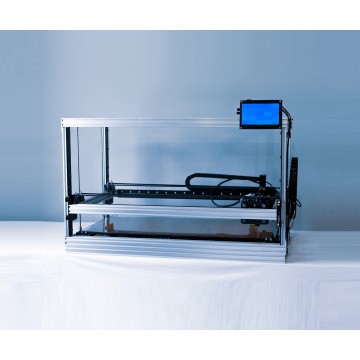

The Stabilus LF1 kit is a large format 3D printer foundation designed as a modular X-Y-Z platform providing strength, power, and flexibility. The LF1 is made from corrosion-resistant, lightweight, extruded aluminum; constructed to be precisely square, ensuring quality operations.

With a 3D printable area of 700mm x 400mm x 300mm the LF1 is 220% larger than a standard printer. With the LF1 your able to print objects over 3 feet long!

Stabilus 2021 Revision

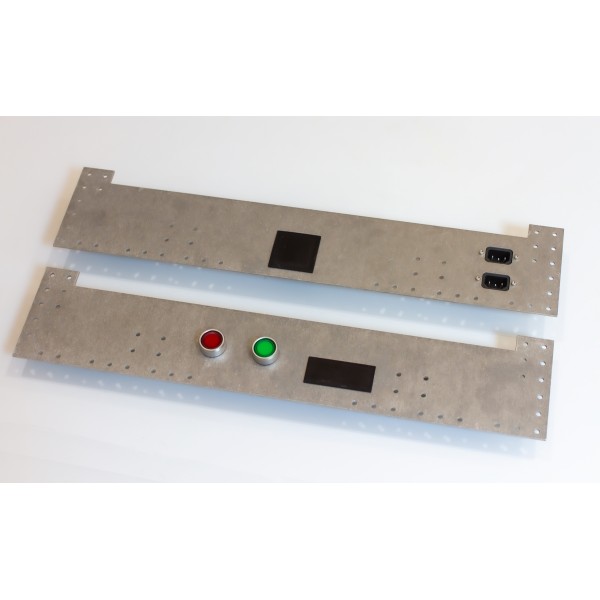

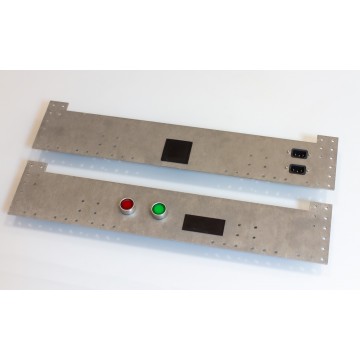

*New* - Dual C14 Panel Mount Power Inlet Plugs

*New* - 2x 22mm cutouts for Push Buttons

*New* - Taller side supports strengthen vertical pillars

*Some images are simulated to show color

The Stabilus frame kit was born from a need to upgrade a standard 3d printer. Most printers are limited in their size and upgrade capabilities. Small modifications can be made, new stepper motors, maybe a new bed, but if you’d like to explore the exotic side of 3d printing you’re going to need a frame to start with. Enter the Stabilus LF1 frame kit. The LF1 is a large, Long Format kit consisting of a rigid rectangular frame to support 3d printer operations. Built in supports and enclosures aid in placement of additional modular items. Let’s say you’d like to expand to an automatic multi filament device. With the Stabilus frame you’ll have plenty of options to mount the hardware directly to the frame. A radiator for water-cooling fits perfectly within the rectangular top frame. If your into tool changing there is a perfect place for a mag-shed where you can store over a dozen tools! There are water durable, thermal covers to support high temperature printing, and dual 22mm button cutouts with two 110v C14 plug inputs to separate power a heated bed or chamber heater. The Stabilus LF1 frame kit was designed with industry standards to provide a useful and functional point to start your projects from.

LF1 Kit Includes:

- 1xTop Frame

- 4x Vertical Columns

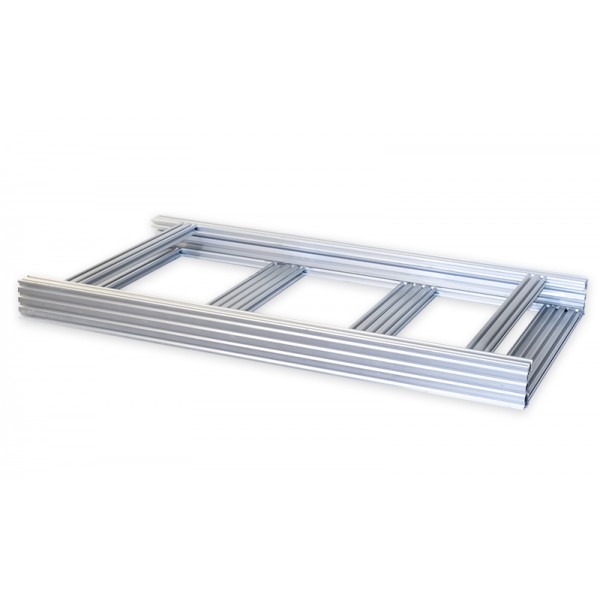

- 1x Bottom Frame

- 1x Gantry Frame

- 2x 580mm Face Plates

- 2x C14 Panel Mount Power Inlet Plugs

- 4x 8-Hole Top Plates Connectors

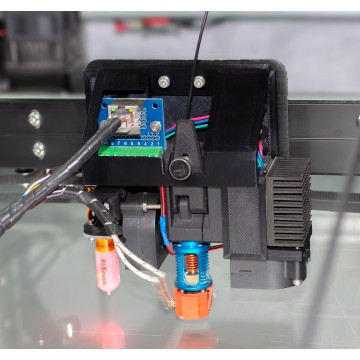

- 1x Print Head Connecting Plate

- 7x Linear Rails

- 7x Cart Kits (Wheels, Plate, Bearings, Nuts and Bolts)

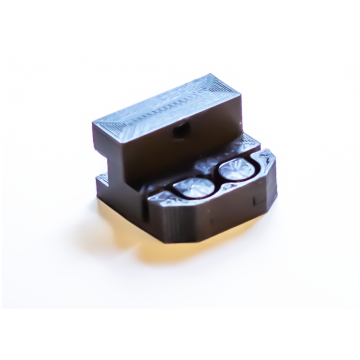

- T-Nuts and 5mm Bolts to connect it all together!

Quad Z, Dual Y, Single X, Single Hotend: The Stabilus frame was designed to support 8 NEMA 17 stepper motors including hotend. Four 44Ncm .9 degree stepper motors for the Z axis. Two 65Ncm high torque motors for Y travel and one 65Ncm high torque motor for X travel. The 3D Printer head was designed for a .9 degree 11Ncm ‘Pancake’ stepper motor. The hotend carriage also supports a BL Touch sensor has a flexible solution for a multitude of extruders. With the optional configuration you can choose whichever hotend or extruder you wish. Our configuration was supports a Bondtech filament extruder attached to a Phaetus Dragon hotend.

Quad Z Stepper Motors: After much trial and error a Quad-Z design proved to be the most constant and flexible. Utilizing G29 and G32 gcode the BL-Touch sensor is able to automatically level and map the print bed. The G29 process probes four corners and communicates individual corrections to each Z stepper motor. Three passes with G29 can level the bed to within a hundredth of a mm. Additional the G32 process probes the bed for with over 440 individual points to create a ‘height map’. These two commands properly used together ensure a level printable surface.

Custom Faceplates: The faceplates were designed to support the four vertical columns, and provide a vertical 4-hole mount for 4 stepper motors. The faceplate is cut from 3.5mm thick 6160 aluminum with 42 individual cutouts for mounting. 2x 22mm cutouts for standard buttons or switches. Two cutouts for C14 110v Power Inlet Plugs, one for the printer operations, and another for a 110v headed bed, or chamber heater. We’ve also included 68x28mm and 42x42mm cutouts for an optional fan, and heated bed or chamber controller. If you choose not to use these cutouts you’ll also receive black faceplate plugs.

The faceplates come in an aluminum, tumbled finish.

The faceplates included in powder coated kits are also powder coated with a matt black finish. If a different color is desired please contact us!

Why black rails when we have linear: Good Question! We’ve been printing personally and professionally for over 10 years and have used both setups. Linear rails are wonderful in smaller setups, but suffer from drag when extended too long and loads are too heavy. Linear rails are hard to get in custom lengths, plus the cost goes way up as the length increases. The LF1 kit was designed with black rails to support a 3 lbs print head in lengths of over 3 feet!

-Can support heavy loads

-Able to support extended lengths

-Easy to clean

-Expandable

-Precise

-Minimal resistance

-Smooth operations

-Much cheaper